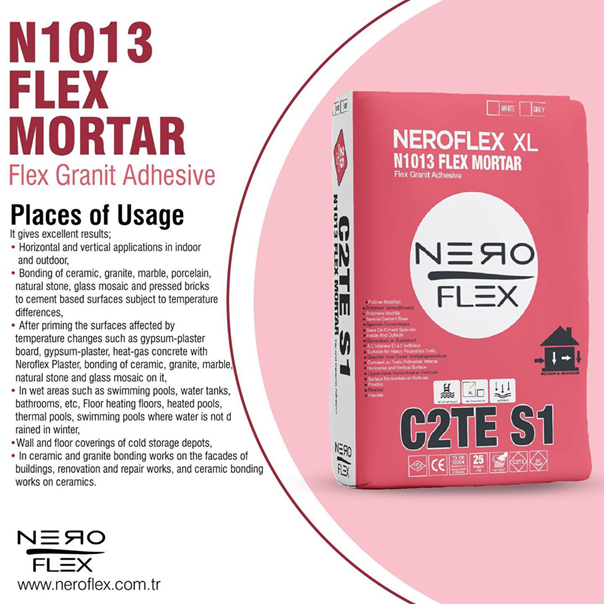

N1013 FLEX MORTAR C2TE S1 Flex Granite Adhesive

N1013 FLEX MORTAR C2TE S1

Flex Granite Adhesive

It is S1 Class flexible, cement based granite adhesive mortar with high performance, reduced slip property, long working time.

Consumption: Average 4-5 kg/m2

Package: In 25 kg kraft bags.

N1013 FLEX MORTAR C2TE S1

Quality Certificates:

Manufactured according to TS EN 12004.

C : Cement based

2 : High performance

T : Reduced slip property

E : Prolonged working time

S1 : Flexible

Places of Usage

It gives excellent results;

• Horizontal and vertical applications in indoor and outdoor,

• Bonding of ceramic, granite, marble, porcelain, natural stone, glass mosaic and pressed bricks to cement based surfaces subject to temperature differences,

• After priming the surfaces affected by temperature changes such as gypsum-plaster board, gypsum-plaster, heat-gas concrete with Neroflex Plaster, bonding of ceramic, granite, marble, natural stone and glass mosaic on it,

• In wet areas such as swimming pools, water tanks, bathrooms, etc, Floor heating floors, heated pools, thermal pools, swimming pools where water is not drained in winter,

•Wall and floor coverings of cold storage depots,

• In ceramic and granite bonding works on the facades of buildings, renovation and repair works, and ceramic bonding works on ceramics.

Features/ Advantages

• It has long penetrating time.

• easy to prepare and apply.

• Does not slip in vertical surface applications.

• Resistance to freeze-thaw cycle.

• resistance to stresses and vibrations caused by temperature differences.

Application Directions:

a) Surface Preparation:

Take care that the application surface should be solid, dry, carrier, dust-free and clean and at the same time in balance. The surface should be thoroughly cleaned of all kinds of oil, grease, rust and paraffin residues that will weaken the adherence and there should be no loose particles on the surface. Damaged surfaces with a depth of 5 to 20 mm should be repaired with Neroflex Repair Mortars two days in advance. If the temperature of the surface to be applied is above + 25°C, the surface should be moistened. On Plaster Based Surfaces, Neroflex Plaster is applied on gypsum-paper board, gypsum-plaster, gas concrete, lime stuff and chipboard with high absorbency. Adhesion can be started 5 minutes after the primer application. Wood Particleboard Surfaces (OSB and Chipboards), Wood particleboards should contain a maximum moisture content of 10% . Wood particleboard (V100) applied to the floors should be minimum 25 mm and 19 mm for the walls. The boards should be screwed to the surface at 30 cm intervals. The edge joint must be at least 8 mm wide. At the joints of the chips, grooves should be opened and filled with Joint Sealant. Wood paperboards should be primed with Neroflex Plaster in dry environments. If the boards are in place that exposed to moisture (exterior), it is applied with Fully Flexible Waterproofing Material in two layers and mesh reinforced.

b) Product Preparation:

The water in appropriate amount is poured into the clean mixing vessel with a scale. N1013 Flex Mortar is added slowly and mixed with a 400-600 rpm mixer for 3-5 minutes until a uniform and lump-free mixture is obtained. After resting for 3-5minutes and mixing again for 30 seconds, the material is ready for use.

c)Application Method:

N1013 Flex Mortar layer of 1 mm thickness is applied to the application surface with the flat side of the trowel. N1013 Flex Mortar is applied in one direction in such a way that a uniform thickness is obtained with the toothed side of the trowel to an area that can be covered within 30 minutes, open waiting time. For the bonding of tiles or ceramics with different thicknesses, it is recommended to apply 1 mm thick mortar under each tile or ceramic in order to cover the defects on the application surface. When applying tiles or ceramics in place, the tiles or ceramics are floated in the mortar to ensure that the N1013 Flex Mortar is fully in contact. Application is completed by leaving the recommended joint gap according to the appropriate tile or ceramic size. Neroflex Joint Fillings should be used to fill the left joint gaps. Joints can be applied after approximately 24 hours

Issues to be Considered

• Avoid application at temperatures below + 5°C and above+ 35° c.

• Pay attention to the amount of water added to the mortar. Do not add more water than necessary.

• Avoid application in areas that are frozen, at risk of freezing within 24 hours or exposed to direct sun and wind.

Cleaning of Tools:

Tools and equipment used should be cleaned with water after the application. 1014 Performans can only be removed mechanically from the surface after hardening.

Security Warnings

• S2 Keep out of the reach of children.

• S24/25 Avoid contact with eyes and skin.

• S26 In contact with eye, wash with water and consult a doctor.

• S28 In contact with skin, wash immediately with plenty of water.

• S29 Do not empty into drains.

• S46 If swallowed, consult a doctor immediately and show box or label.

Consumption: Average 4-5 kg/m2

Package: In 25 kg kraft bags.

N1013 FLEX MORTAR C2TE S1

Quality Certificates:

Manufactured according to TS EN 12004.

C : Cement based

2 : High performance

T : Reduced slip property

E : Prolonged working time

S1 : Flexible

Other Products

Export to the Middle East and Europe

Production with Special Production Techniques

Recipes for All Needs

Full Time Secure Shipping