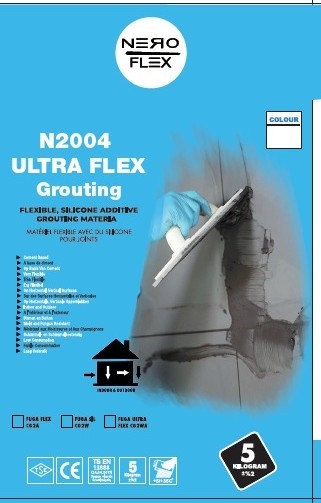

N2003 FUGA Sil CG2W Silicone Grouting

N2003 FUGA Sil CG2W

Silicone Grouting

It is a high performance, silicone, cement based joint filter that can be used indoors and outdoors, suitable for 1-6 mm joint gap.

Consumption: See Joint Filler consumption table.

Package: 20 kg kraft bags.

5 kg polyethylene sack

1 kg polyethylene sack

N2003 Fuga Sil CG2W

Quality Certificates:

Manufactured according to TS EN 1 3888.

C : Cement based

G : Grouting

2 : High performance

W : Reduced water absorption

Places of Usage:

• It is used for;

• Indoor and outdoor,

• Horizontal and vertical applications,

• In wet areas such as pools, baths, toilets and easily contaminated places such as kitchens,

• In areas such as water tanks, Turkish baths and saunas that are exposed to water continuously and maid formation is observed rapidly,

• Filling joints of up to 1-6 mm of granite ceramic, large ceramic, tile, natural granite, marble, clinker and glass mosaic coatings.

Features/ Advantages:

• It has not fading, dusting and cracking.

• Resistant to dirt formation.

• Thanks to its silicone additive, it is water repellent and can be used safely in wet areas.

• Resistant to maid and fungus formation.

• Provides smooth surface.

• Water and frost resistant.

• Adheres perfectly to the ceramic edges without cracking.

• Offers a rich color selection and is decorative.

• Resistant to abrasion.

Application Directions:

a) Surface Preparation:

It should be paid attention that the ceramics are well adhered in order not to move during application, and the adhesive should be completely dry. Any dust, dirt, sawdust, construction and cement residues remaining in the joint gaps on the surfaces where the flooring process is completed should be thoroughly cleaned with a thin rod or brush. Make sure that the joint gaps are at least 2/3 of ceramic thickness. The cleaned gaps should be moistened with a wet sponge.

b) Product Preparation:

20 kg N2003 Fuga Sil joint filter (1-6 mm) is added into about 6-7 It of clean water and mixed preferably with a low speed mixer until no lump remains. Because joint fitler added to the water is silicone additive, there may be difficulties in the mixing in the first place. Continue mixing with the mixer until a homogeneous appearance is achieved. Pay attention to the amount of water to be added to the powder mortar, avoid application in the form of grout added excess water. Excess water added to the mortar will cause cracking, easy wear and dusting. The prepared grouting material in thick consistency is left to rest for 5 -1 0 minutes for maturation and used after mixing for 1 -2 minutes again. The mixture in the container should be consumed within about 1 hour.

c)Application Method:

The joint sealant must be filled into the Joints with a hard rubber tipped squeegee or hard rubber based joint spreading trowel. In order to fully fill the gaps, they must be pulled first parallel and then crosswise. The excess of the mortar on the surface should be peeled off with a moistened soft tip spatula, after waiting for 15-30 minutes according to the ambient temperature, wiped with a damp sponge and the thin joint layer that may remain on the surface should be cleaned thoroughly.

Joint cleaning should not be started prematurely. It should not be wiped with excess wet sponge in order not to cause color fluctuation. The sponge used should be cleaned frequently. It dries on walls after 24 hours, can be walked on floors after 48 hours, can be opened to pedestrian traffic after 7 days.

Issues to be Considered:

• Avoid application at temperatures below +5° C and above+ 35° C.

• Avoid application in areas that are frozen, at risk of freezing within 24 hours or exposed to direct sun and wind.

• Never add water and powder to the mortar that has expired.

• Do not clean the joints with salt spirit, bleach etc. products. Use Neroflex Joint Cleaner for cleaning.

• The amount of consumption indicated is general information.

Cleaning of Tools:

Tools and equipment used should be cleaned with water after the application. N2003 Fuga Sil can only be removed mechanically from the surface after hardening.

Security Warnings:

• S2 Keep out of the reach of children.

• S24/25 Avoid contact with eyes and skin.

• S26 In contact with eye, wash with water and consult a doctor.

• S28 In contact with skin, wash immediately with plenty of water.

• S29 Do not empty into drains.

• S46 If swallowed, consult a doctor immediately and show box or label.

Storage:

It should be stored in unopened original package in a cool and dry environment by protecting from frost. For short-term storage, maximum 3 pallets should be placed over and over and the shipment should be made with first in first out system. For long-term storage, pallets should not be placed

over and over. It can be stored for 12 months from the date of production if proper storage conditions are met. Opened packages should be kept tightly closed and stored under proper storage conditions and should be used within one week.

Consumption: See Joint Filler consumption table.

Package: 20 kg kraft bags.

5 kg polyethylene sack

1 kg polyethylene sack

N2003 Fuga Sil CG2W

Quality Certificates:

Manufactured according to TS EN 1 3888.

C : Cement based

G : Grouting

2 : High performance

W : Reduced water absorption

Export to the Middle East and Europe

Production with Special Production Techniques

Recipes for All Needs

Full Time Secure Shipping